Auto & Motor Parts

- …

Auto & Motor Parts

- …

Engineering-Driven Aluminum Components for EV, Automotive & Racing Applications

Precision CNC machining, die casting, and extrusion with system-level engineering insight.

Aluminum Components by Application

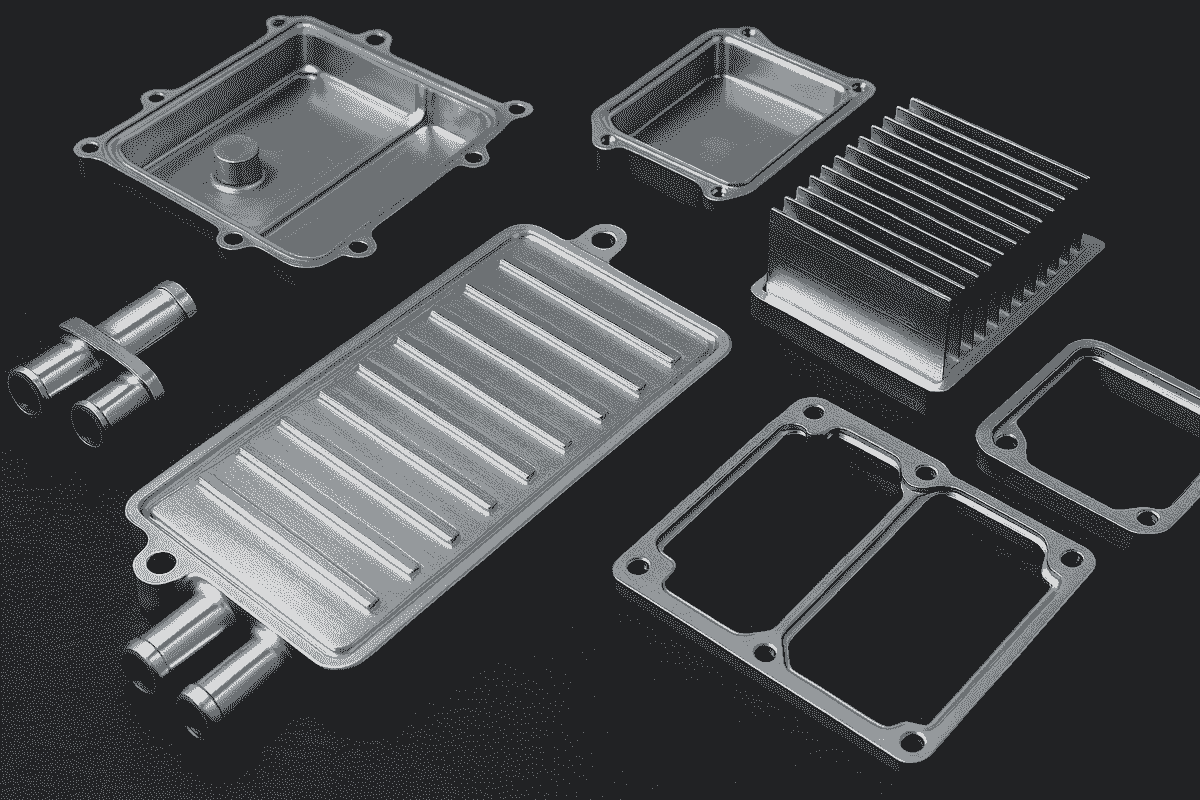

We focus on custom aluminum components for EV, energy storage, power electronics and performance vehicles. Our main product lines include:

EV & Energy Storage Components

Engineering-grade aluminum components for EV and ESS systems where thermal performance, structural integrity, and long-term stability are critical.

Typical parts include battery housings, cooling-related components, and power electronics enclosures.

Automotive Components

Functional and structural aluminum parts for automotive applications requiring dimensional accuracy, durability, and scalable production.

Motorcycle & Racing Components

High-precision aluminum parts for motorcycle, racing, and aftermarket applications where appearance, weight, and machining quality matter.

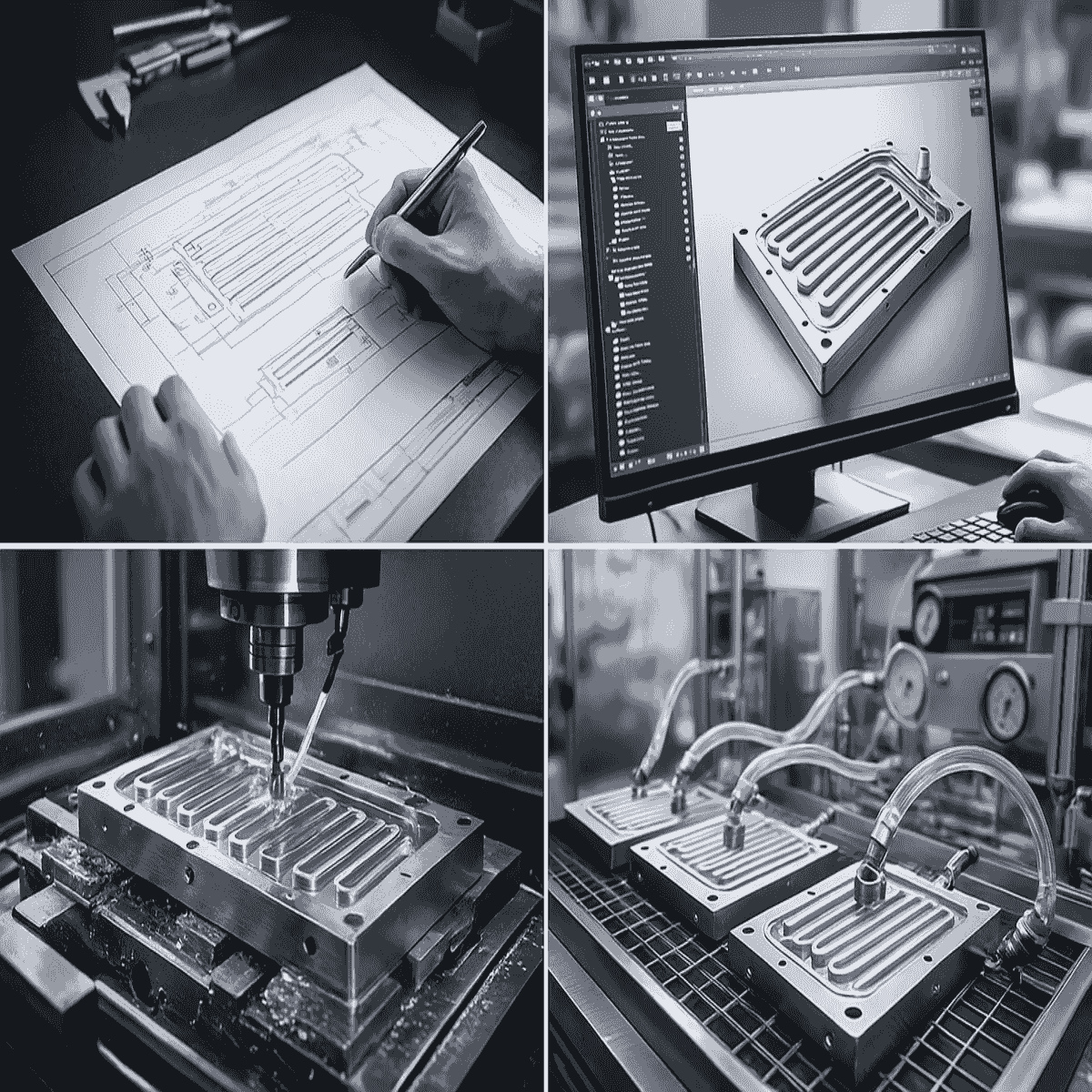

How We Choose the Right Manufacturing Process

Manufacturing process selection is not based on equipment availability alone.

We evaluate application requirements, system role, production volume, and failure risk before recommending CNC machining, die casting, or aluminum extrusion.👉 CNC vs Die Casting vs Extrusion for Aluminum Cooling Component

Who We Serve?

We work with engineers, product teams and buyers from:

EV and hybrid vehicle manufacturers

Energy storage system (ESS) providers

Power electronics and inverter manufacturers

Automotive aftermarket brands

Motorcycle & racing teams

Industrial equipment and machinery makers

Why Work With Wometal?

Your aluminum partner for racing, tuning and EV projects. We don’t just manufacture parts — we help reduce engineering and production risk.

Engineering-Driven

We understand drawings, materials and manufacturing limits — not just prices.

We support DFM, tolerance discussion and process optimization to help you avoid costly mistakes.

Aluminum-Focused

We specialize in aluminum components for EV, ESS and power electronics — including cooling plates, housings, brackets and enclosures.

Flexible & Fast Production

Prototype, small batch and scalable production with flexible MOQ and responsive lead times — ideal for fast-moving engineering teams.

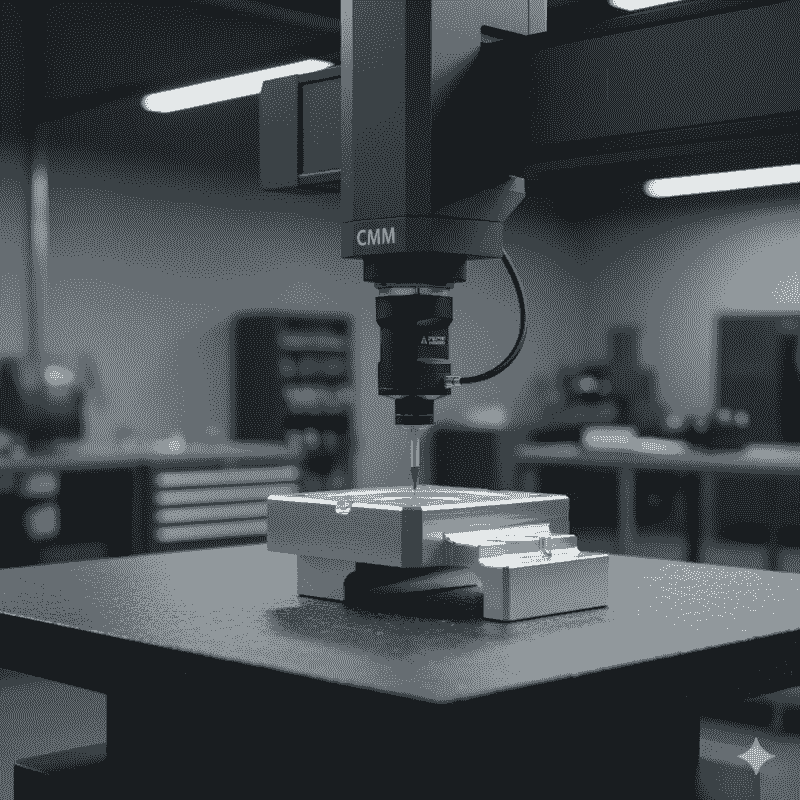

Reliable Manufacturing & Quality Control

Stable manufacturing capability with consistent CNC, die-casting, anodizing and inspection processes — including CMM measurement and leak testing for critical components.

Manufacturing Capabilities

From raw material to fully finished aluminum components, we support key processes required for EV, ESS and performance applications.

- CNC Machining

Precision machining for complex geometries, sealing surfaces, and safety-critical features across EV, automotive, and performance applications.

- Die Casting + Machining

Cost-efficient production for high-volume structural aluminum components, with CNC post-machining for critical interfaces and assembly features.

- Aluminum Extrusion

Stable and scalable solutions for long-length structural and cooling profiles, optimized for consistency and production efficiency.

- Anodizing & powder coating

Durable surface finishing for corrosion resistance, aesthetics and optimized thermal performance.

- CMM measurement and dimensional inspection

Full dimensional reports for critical mating areas, sealing surfaces and assembly-fit validation.

- Leak testing for cooling plates and housings

Pressure and vacuum leak tests ensuring reliability in EV and energy-storage liquid-cooling systems.

Featured Projects

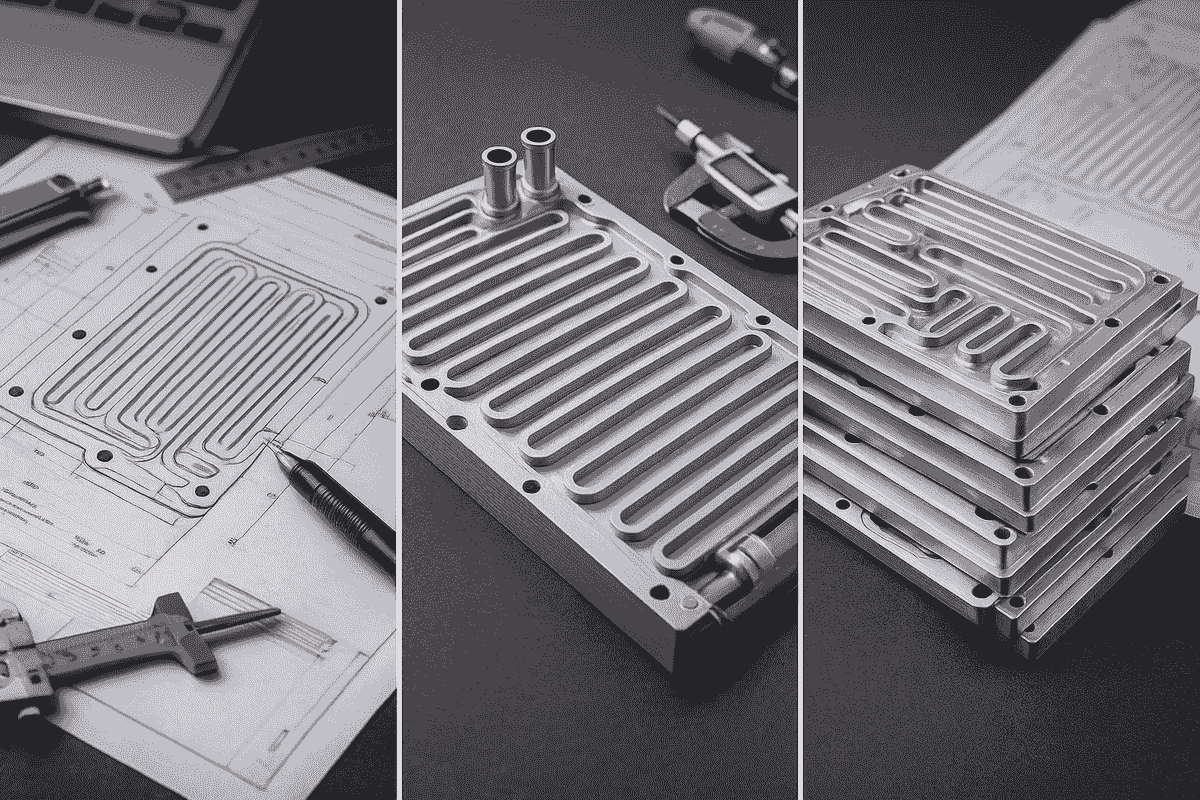

EV Cooling Plate Prototype

EV Cooling Plate Prototype for a European Startup

Material: 6061-T6 aluminum

Process: CNC machining + welding + leak test

Result: From concept to tested prototype in 3 weeks, ready for system integration.

Battery Housing for Energy Storage

Battery Housing for ESS Manufacturer

Process: Die casting + CNC + anodizing

Focus: Flatness, sealing surfaces and mounting accuracy

Result: Stable batch supply with improved assembly efficiency.

Billet Racing Component

Billet Aluminum Part for Racing Application

Process: CNC machining + color anodizing

Focus: Appearance, tolerance and weight reduction

Result: Lightweight and visually distinctive component for performance brand.How We Work

1Share Your Drawing or Idea

Send us 2D/3D files or even a concept sketch.

2Engineering Review

We check materials, process feasibility, risks and cost drivers.

3Quotation & Proposal

You receive a clear quote with recommended process and lead time.

4Prototype & Validation

We produce samples, support testing and make adjustments if needed.

5Production & Long-Term Support

Scale up to stable supply with consistent quality and communication.

About Wometal

Wometal is an engineering-driven studio focused on custom aluminum components.

We specialize in EV thermal systems, energy storage structures, power electronics housings and performance vehicle parts.Our mission is simple:

Make high-quality aluminum manufacturing clear, reliable and accessible to companies of any size.COME AND VISIT US

We offer high-quality auto parts including fuel tank caps, door handles, and gear shift knobs. Come visit us to see our products and learn more about our company. Our products meet or exceed OEM specifications for a perfect fit and long-lasting performance.

Engineering Insights

December 26, 2025Introduction In aluminum cooling components for EV, automotive, and energy-related applications...Introduction In EV and energy storage system (ESS) projects, thermal design decisions are...December 23, 2025Introduction In engineering discussions, one phrase appears very frequently: “Technically,...December 23, 2025Introduction When designing aluminum liquid cooling plates for EV and ESS applications, the...Ready to Develop Your Next Aluminum Component?

Share your drawing or idea — we’ll respond with engineering feedback or a quotation within 24 hours.

FAQs

We know starting a custom aluminum project comes with many questions about lead time, MOQ, materials and quality. Here are some quick answers.

Q: Can you make custom parts based on my drawings or samples?

Q: What is your typical lead time for prototypes and production?

Q: What is your minimum order quantity (MOQ)?

Q: Can you help optimize drawings?

Q: What materials and finishes can you provide?

Q: How do you ensure quality?

Q: What happens if there is a quality issue?

Q: Do you support international shipping?

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.